Winemaking

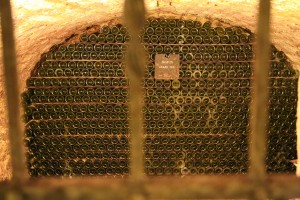

The Baron’s experience in modernizing the Ladoucette cellars in Pouilly-sur-Loire inspired him to make similar changes at Régnard, including thermo-controlled stainless steel fermentation tanks and sodium lamps in the aging sheds to prevent light damage.

During the harvest, all the grapes are handpicked and then pressed. The must then passes into a small vat for natural clarification and the juice is transferred to stainless steel tanks for malolactic fermentation. Four different types of yeast are used for fermentation, each bringing a specific character to the wine. This enables Régnard to achieve great complexity in their wines. Each tank receives cultural yeast to start the fermentation.

The temperature of the fermentation is regulated at 68-71ºF by water that is circulated in the double lining of the tank. After the first fermentation, all of the wine undergoes malolactic fermentation. Bacteria is added to begin this fermentation, which reduces the wine’s acidity and gives it more complexity and stability.

Next, the wine is racked to remove the lees and fined using a fining agent. After blending, the wine undergoes a cold process to extract tartrate deposits. The wine is then filtered before bottling.